About Us

We are committed to comply with our code

Build Safe . Build Smart

Sunnyquick is a company specialized in customizing Aluminum doors, windows and glass curtain wall systems designed for different customers to meet various types of buildings such as: Hotels, Commercial buildings, Residences and Apartments.

We have a large number of high-precision equipment and a professional quality control department, established and operated in line with a strict product quality control system.

All our products strictly comply with the performance specifications of waterproof, windproof, noise reduction, sun protection and flame retardant. We also have our own efficient development system, which can provide greater flexibility for different architectural designs and configurations. Our goal is to produce reliable and safe building material solutions that meet the building codes of your country/region. This allows them (Individual buyers, residents, and commercial project contractors) to establish long-term business partnerships and achieve a win-win situation.

Global Projects

Successfully projects finished in America, Canada, Uruguay, Australia, New Zealand, Philippines, Maldives, Qatar, Nigeria, Ethiopia, etc.

long-termism

One of the best representatives of Chinese manufacturing exporters, valuing reputation and quality, a reliable long-term supplier.

Teamwork

16 teams of construction workers. More than 200 production technicians, more than 10% R&D engineers.

130

Assist customers’ revenue in 2018 investment(Million)

980

Cooperating Partners

512

Successfully Project

15

Year of Experience

Factory Introduction

Over the years, Sunnyquick has been dedicated to the R&D, design, manufacturing, process improvement and innovation of high-performance curtain wall, window and door products. The company has reached the international level in such major technical fields as R&D, design, manufacturing and construction.

CNC Processing Center

Processing Line

Container Loading

Vertical Powder Coating Production Line

Anodized Aluminum

PVDF Production Line

Hardware Endurance Test

Tempered Glass Production Line

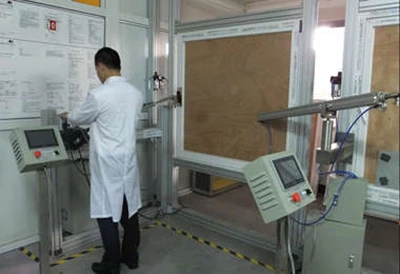

Important Performance Test

Manufacturing Introduction

Sunnyquick’s manufacturing facility is built around total quality management, lean manufacturing and kaizen principles ensuring control of quality, accuracy and efficiency. Our processes have been certified by ISO 9001 standards. Our facilities include adjacent design and production areas, contributing to the dynamics of innovation and collaboration. Furthermore, by fostering partnerships with material vendors and product suppliers around the globe, Sunnyquick has been able to maintain complete control over its supply chain, further enhancing our capability to deliver cost effective solutions.

All quality control tests of Sunnyquick are carried out by independent third parties as per the latest international norms, in line with the project specifications. Sunnyquick’s manufacturing process goes through rigorous quality control exercises both by human and computerized testing.This along with the time-tested skill and craftsmanship of the Sunnyquick team of operatives has a well defined edge on shaping components with unerring precision and finish.

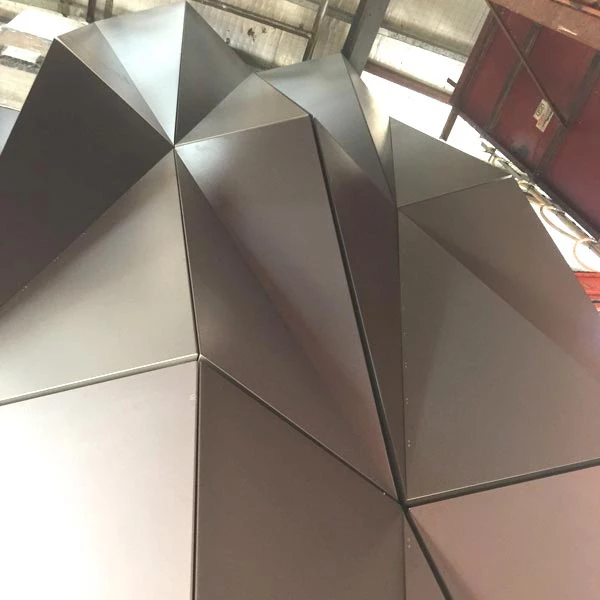

We specialize in manufacturing of building facade systems, glass curtain wall systems, unitized curtain walls, frame structured curtain walls, aluminium windows and doors, aluminium louvers, railing etc…

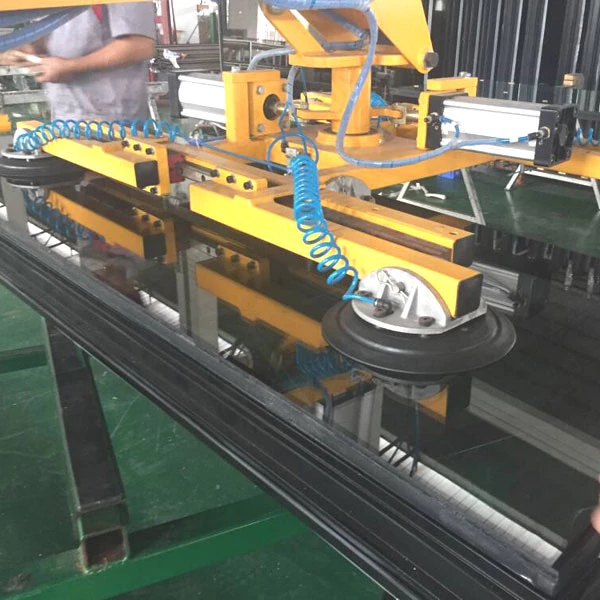

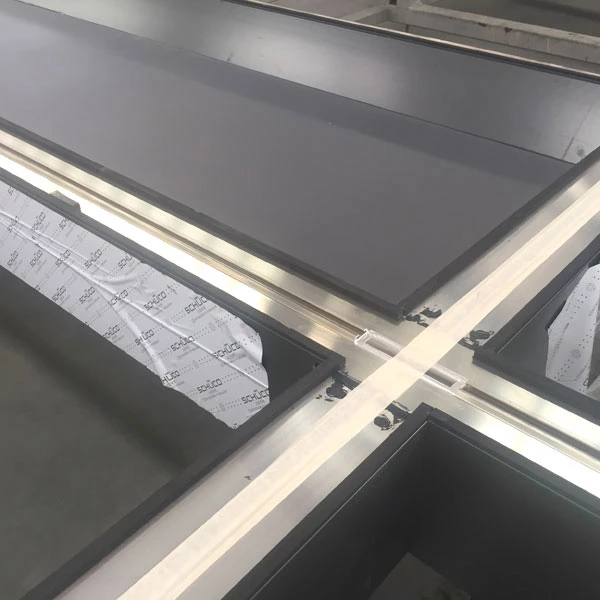

Curtain Wall Manufacturing

In the constant temperature room, a experienced technician was injecting the DOW CORNING structural glue into the aluminum plate connection.

The suction cup boom robot is moving a heavy unitized curtain wall glass panel which human can’t move.

Unitized glass curtain wall panel standard export package, ideal for container and shipping, ensuring cargo safety.

Aluminum curtain wall samples are being tested in Singapore with the most authoritative and rigorous testing.

The Schüco curtain wall system profiles selected according to the project requirements are being assembled.

With a professional angle machine, the sealing and strength of the aluminum window can be upgraded to excellent quality.

Windows & Doors Manufacturing

Cutting: Compared with the single saw, the aluminum material uses the double-headed saw, which greatly reduces the error, and the tolerance accuracy is 0.1-0.3mm,thus reach a good performance on waterproof, windproof.

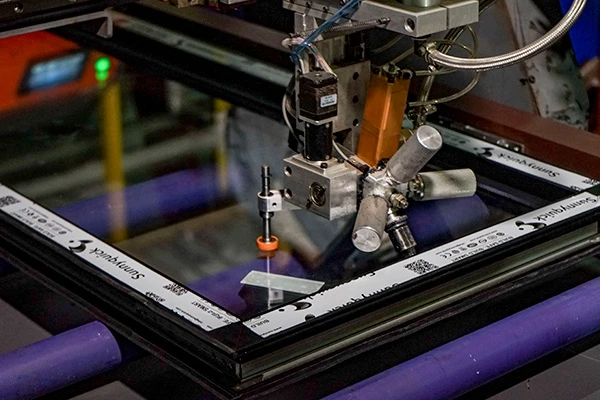

Milling Keyhole: Using CNC automatic data processing center milling equipment can accurately create keyhole size.

Milling Port: The port connection is milled to avoid the position and make the port seamlessly connect.

Machine wire group angle and glue injection: The ordinary impact angle corner strength is 80-100kg. When injected with imported glue, the strength can reach 500kg.

Machine wire group angle and glue injection: The ordinary impact angle corner strength is 80-100kg. When injected with imported glue, the strength can reach 500kg.

Install rubber strips: Automotive-grade high-quality rubber strips, with EPDM material can reach 15-20 years service life, while the life of ordinary rubber strips on the market is only 5-10 years.

Install hardware: Standard domestic premium brand, optional imported hardware from Germany.

Safety: children safety protection, with children’s safety handle function.

Testing the installation handle: The durability is more than twice that of ordinary handles, and the usage frequency is more than 50,000-100,000 times.

Anti-theft: When the window is closed or inverted, the window handle and the square shaft are disengaged from each other, and the handle is automatically locked.

Silicone glue: Glue application advantages: waterproof and sealed

Adhesive strip advantages: excellent weather resistance, convenient glass replacement–this is optional

CNC automatic glue equipment advantages: stable, reliable and beautiful

Our service

One-stop Solutions

Design

Measurement

Solution

Certification

Manufacturing

Logistics

Installation

After sale service

Sustainability

Committed To Keep Long Term Development of Customers

Empower customers to achieve optimal investment returns through design and product manufacturing.

Build Safe . Build Smart

Safety stands as the cornerstone of project construction, smart heralding the future of advanced technological advancement.

- Sustainablility

- Project On Time

- Modern Technology

- Latest Designs

Contact Now

Address

B12, Liandong Technology Innovation Park, Foshan, Guangdong, China

terry@sunnyquick.com

Phone

+86 136 3240 4947

+86 136 3240 4947